Understanding Vapour Blasting: Diy Vapour Blasting Cabinet

Vapour blasting is a versatile and effective cleaning and surface preparation technique that uses a high-velocity stream of abrasive particles suspended in a water-based slurry to remove contaminants, rust, paint, and other coatings from a variety of surfaces. It is a powerful and precise method that delivers superior results compared to traditional cleaning methods.

The Science Behind Vapour Blasting

Vapour blasting operates on the principle of using a combination of kinetic energy, abrasive particles, and a water-based slurry to achieve cleaning and surface preparation. The process involves creating a high-velocity stream of abrasive particles suspended in a water-based slurry. This slurry is then directed at the surface to be cleaned. The abrasive particles, propelled by the high-velocity stream, impact the surface and remove contaminants, rust, paint, and other coatings. The water-based slurry acts as a lubricant and cooling agent, reducing heat generation and minimizing damage to the underlying material.

Advantages of Vapour Blasting

Vapour blasting offers several advantages over traditional cleaning methods:

- Precision and Control: Vapour blasting provides precise cleaning and surface preparation, allowing for controlled removal of contaminants and coatings without damaging the underlying material.

- Gentle Cleaning: The water-based slurry acts as a lubricant and cooling agent, reducing heat generation and minimizing damage to the underlying material, making it suitable for delicate surfaces.

- Environmentally Friendly: Vapour blasting is an environmentally friendly process that uses water-based slurries and minimizes the use of harmful chemicals.

- Versatility: Vapour blasting can be used on a wide range of materials, including metals, plastics, ceramics, and composites, making it a versatile cleaning and surface preparation technique.

Types of Vapour Blasting Equipment

There are various types of vapour blasting equipment available, each suited for specific applications:

- Handheld Vapour Blasters: These are portable and compact units suitable for small-scale cleaning and surface preparation tasks.

- Stationary Vapour Blasters: These are larger units designed for industrial applications, offering high-volume cleaning and surface preparation capabilities.

- Robotic Vapour Blasters: These are automated systems that utilize robots to perform cleaning and surface preparation tasks, enhancing precision and efficiency.

Abrasive Media Used in Vapour Blasting, Diy vapour blasting cabinet

Different types of abrasive media are used in vapour blasting, each with specific characteristics and applications. Here is a table comparing various abrasive media:

| Abrasive Media | Characteristics | Applications |

|---|---|---|

| Glass Beads | Fine, rounded particles that provide a smooth finish. | Cleaning and deburring delicate surfaces, polishing, and removing light rust. |

| Aluminum Oxide | Hard and durable particles that offer aggressive cleaning and surface preparation. | Removing heavy rust, paint, and coatings, preparing surfaces for welding and coating. |

| Walnut Shells | Natural and biodegradable particles that provide a gentle cleaning action. | Cleaning and deburring delicate surfaces, removing light rust and paint, and preparing surfaces for coating. |

| Plastic Media | Soft and non-abrasive particles that provide a gentle cleaning action. | Cleaning and deburring delicate surfaces, removing light contaminants, and preparing surfaces for coating. |

Building a DIY Vapour Blasting Cabinet

Building your own vapour blasting cabinet can be a rewarding project, allowing you to restore and refinish various items without needing to purchase expensive commercial equipment. This project requires careful planning and execution, but with the right materials, tools, and safety precautions, you can create a functional and safe vapour blasting cabinet for your workshop.

Materials and Tools

The materials needed for constructing a vapour blasting cabinet can vary depending on the size and complexity of the project. However, some essential materials and tools include:

- A sturdy base, such as a metal frame or a wooden platform, to support the cabinet structure.

- Sheets of metal or plywood for constructing the walls and the lid of the cabinet.

- A blast nozzle and a hose for connecting the nozzle to the vapour blasting system.

- A ventilation system, including a fan and a dust collection system, to remove dust and vapours generated during blasting.

- A vapour blasting system, which includes a compressor, a pressure tank, and a blasting media container.

- A pressure gauge to monitor the pressure in the system.

- Safety gear, including a respirator, safety glasses, and gloves.

- Other tools, such as a drill, a saw, a tape measure, and a level, for assembling the cabinet.

Cabinet Construction

The design of the vapour blasting cabinet is crucial for ensuring its functionality and safety. Here is a basic design that can be adapted based on your needs and resources:

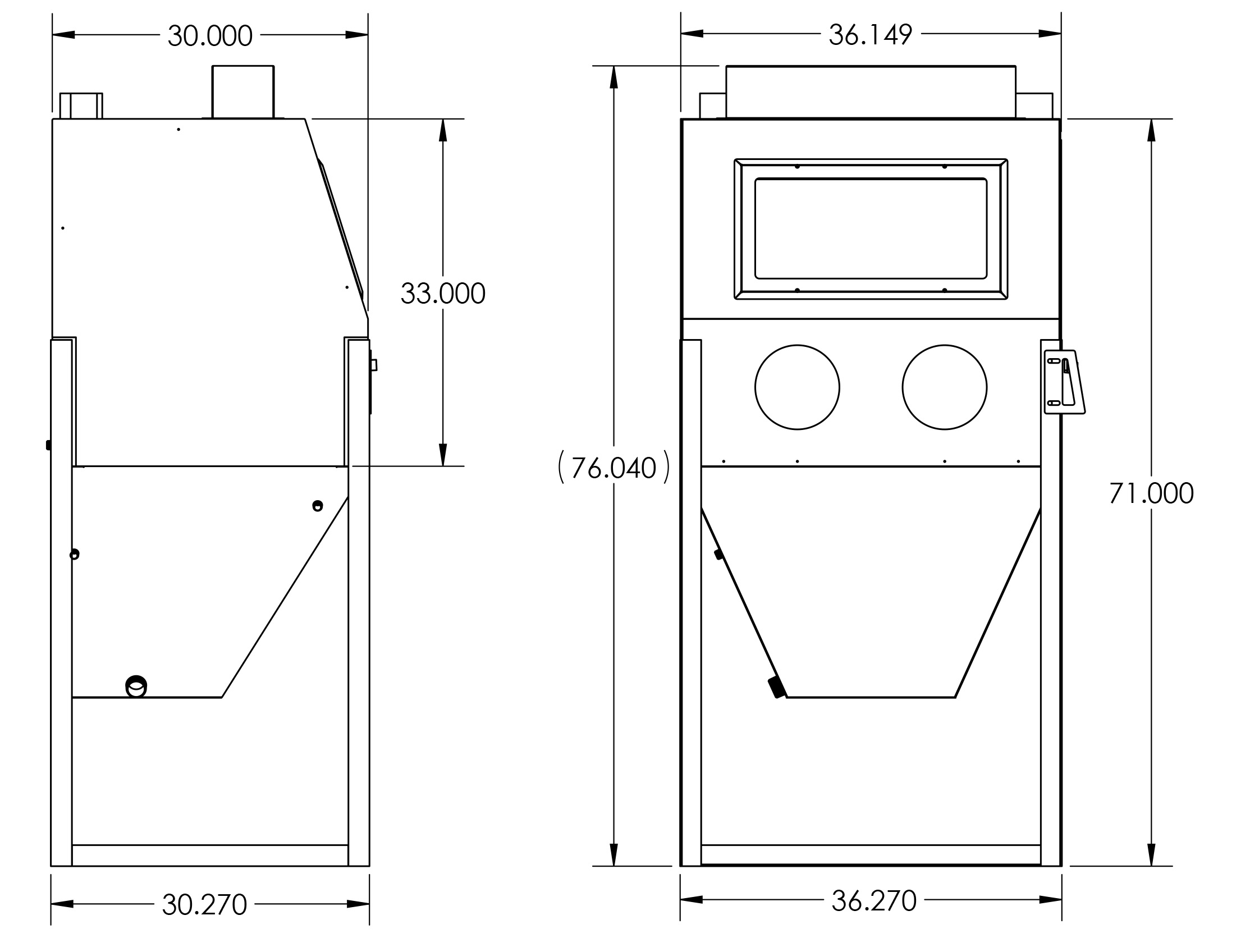

- The cabinet should be large enough to accommodate the items you intend to blast. A standard size for a DIY cabinet is approximately 3 feet wide, 3 feet deep, and 4 feet tall.

- The walls and lid should be constructed from durable materials, such as metal or plywood, to withstand the pressure and abrasive nature of the blasting process.

- The cabinet should have a secure lid with a gasket to prevent dust and vapours from escaping.

- The lid should have a small opening for inserting the blast nozzle and a viewing window for monitoring the blasting process.

- The cabinet should be equipped with a ventilation system to remove dust and vapours generated during blasting.

- Begin by assembling the base of the cabinet. This can be a metal frame or a wooden platform, depending on your chosen materials. The base should be strong enough to support the weight of the cabinet and its contents.

- Cut the metal or plywood sheets to the desired dimensions for the walls and the lid of the cabinet. Make sure the dimensions are accurate to ensure a tight fit.

- Secure the walls to the base using screws or bolts. The walls should be securely attached to prevent any movement during the blasting process.

- Attach the lid to the cabinet using hinges. The lid should have a gasket to prevent dust and vapours from escaping.

- Install the blast nozzle opening and the viewing window in the lid. Make sure the openings are securely sealed to prevent leaks.

- Install the ventilation system. This system should include a fan and a dust collection system. The fan should be powerful enough to effectively remove dust and vapours from the cabinet. The dust collection system should be properly sealed to prevent dust from escaping into the workshop.

Setting Up and Operating the Vapour Blasting System

Before operating the vapour blasting system, it is essential to understand the principles of vapour blasting and the safety precautions involved. Here is a step-by-step guide on setting up and operating the system:

- Connect the compressor to the pressure tank and the blasting media container. The compressor should be powerful enough to provide the required pressure for blasting.

- Fill the blasting media container with the desired blasting media. The type of blasting media used will depend on the surface being blasted and the desired finish.

- Connect the blast nozzle to the hose and attach the hose to the pressure tank. The blast nozzle should be chosen based on the size and shape of the items being blasted.

- Open the valve on the pressure tank and slowly increase the pressure to the desired level. The pressure should be monitored using a pressure gauge.

- Place the item to be blasted inside the cabinet and close the lid securely. Make sure the lid is properly sealed to prevent leaks.

- Turn on the ventilation system and allow the cabinet to purge for a few minutes. This will help remove any dust or vapours present in the cabinet.

- Start the blasting process by holding the blast nozzle at a safe distance from the surface being blasted. The distance will depend on the type of blasting media and the desired finish.

- Move the blast nozzle across the surface in a consistent and overlapping pattern. This will ensure a uniform finish.

- Once the blasting process is complete, turn off the ventilation system and allow the cabinet to cool down. This will prevent any damage to the cabinet or the blasting system.

Ventilation and Dust Collection

Ventilation and dust collection are crucial for ensuring a safe and healthy working environment when using a vapour blasting cabinet. The ventilation system should be designed to remove dust and vapours generated during blasting, while the dust collection system should be properly sealed to prevent dust from escaping into the workshop.

- The ventilation system should be powerful enough to effectively remove dust and vapours from the cabinet. The fan should be rated for the volume of air required to remove the dust and vapours generated during blasting.

- The dust collection system should be properly sealed to prevent dust from escaping into the workshop. This can be achieved using a HEPA filter or a similar dust collection system.

- The dust collection system should be emptied regularly to prevent dust buildup and ensure proper operation.

Applications and Projects for Vapour Blasting

Vapour blasting is a versatile cleaning and restoration technique that can be applied to a wide range of projects, from restoring antique tools to preparing surfaces for painting. Its ability to remove contaminants without damaging the underlying material makes it a valuable tool for both professionals and hobbyists.

Applications of Vapour Blasting

The versatility of vapour blasting makes it suitable for a wide range of applications. Here are some examples:

- Cleaning and Restoration: Vapour blasting is an excellent method for cleaning and restoring various items, including antique tools, machinery parts, engine blocks, and even delicate jewellery. It can remove rust, scale, paint, grease, and other contaminants without damaging the underlying material.

- Surface Preparation: Vapour blasting can effectively prepare surfaces for painting, coating, and plating. It creates a clean and uniform surface, promoting better adhesion and a longer-lasting finish.

- Deburring and Finishing: Vapour blasting can deburr and finish metal parts, creating a smooth and uniform surface. This process is commonly used in manufacturing and aerospace industries to improve the quality and performance of parts.

- Cleaning and Restoration of Historical Artifacts: Vapour blasting is a gentle and effective method for cleaning and restoring historical artifacts, including metal objects, pottery, and even delicate textiles.

- Medical Device Cleaning: Vapour blasting can be used to clean and sterilize medical devices, ensuring they are free of contaminants and ready for use.

Materials Suitable for Vapour Blasting

Vapour blasting can be used on a variety of materials, including:

- Metals: Aluminium, brass, copper, iron, steel, and stainless steel are commonly vapour blasted.

- Plastics: Some plastics, such as acrylic and polycarbonate, can be vapour blasted. However, it’s important to note that not all plastics are compatible with this process.

- Ceramics: Certain types of ceramics, like porcelain and stoneware, can be cleaned and restored using vapour blasting.

Limitations and Risks of Vapour Blasting

While vapour blasting is a versatile technique, it does have some limitations and risks:

- Material Compatibility: Not all materials are suitable for vapour blasting. Some plastics and delicate materials may be damaged by the abrasive action of the blasting media.

- Surface Damage: While vapour blasting is generally a gentle process, it can still cause damage to delicate surfaces. The intensity of the blasting media and the distance from the surface can impact the outcome.

- Safety Considerations: Vapour blasting involves working with high-pressure water and abrasive media, which can be dangerous if not handled properly. It’s crucial to follow safety protocols and wear appropriate personal protective equipment (PPE).

Tips and Tricks for Optimal Results

To achieve optimal results with vapour blasting, consider these tips:

- Choose the Right Blasting Media: The type of blasting media used will depend on the material being cleaned and the desired finish. For delicate materials, a softer media like glass beads is recommended. For tougher materials, a harder media like aluminium oxide can be used.

- Control the Pressure: The pressure of the blasting media will also impact the outcome. A higher pressure will result in a more aggressive cleaning action.

- Maintain Distance: The distance between the nozzle and the surface will affect the intensity of the blasting. A closer distance will result in a more concentrated cleaning action.

- Pre-Clean the Surface: Pre-cleaning the surface with a solvent or detergent can remove loose contaminants and improve the effectiveness of vapour blasting.

- Practice on a Test Piece: It’s always a good idea to practice on a test piece before blasting the actual project. This will help you determine the optimal settings and ensure you achieve the desired results.

Diy vapour blasting cabinet – A DIY vapor blasting cabinet can be a valuable tool for restoring and refinishing metal parts, giving them a fresh, clean look. The process can be particularly useful for restoring the shine of hardware like cabinet bar pulls brushed nickel , which can become dull or tarnished over time.

With a DIY vapor blasting cabinet, you can easily restore their original luster and enhance the overall aesthetics of your kitchen or bathroom.

A DIY vapor blasting cabinet can be a great way to refinish your kitchen cabinets, giving them a fresh look without the hassle of removing them. But before you start stripping and blasting, consider the overall design aesthetic you’re aiming for.

Are you sure gray cabinets are still the right choice? This article explores the enduring appeal of gray, but remember, a vapor blaster can help you achieve a variety of finishes, from sleek modern to rustic farmhouse, so don’t be afraid to experiment with color and texture.